BASIC INFO.

Product Description.

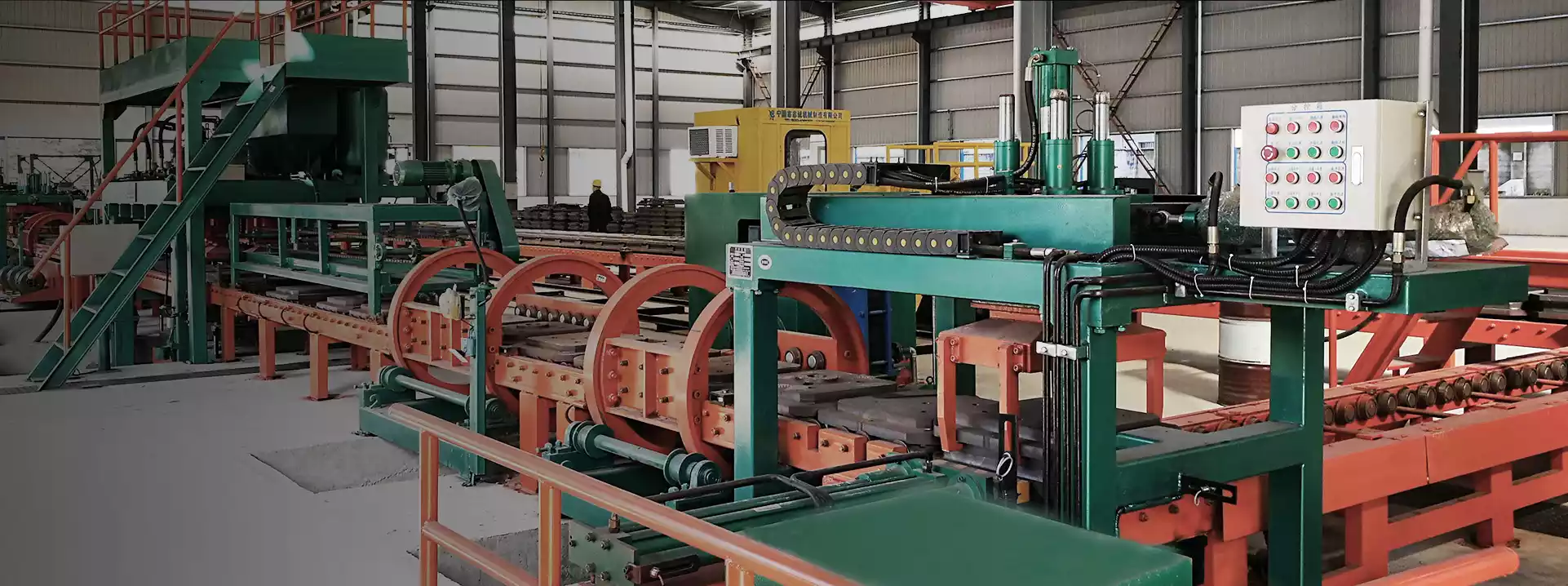

Ball to clean up, separation and sorting of production pattern after cooling to carry on the design and use of machinery and equipment to complete the ball with the separation of the riser, sorting, cleaning, conveying, PLC automatic control, according to different specifications of the ball casting, casting riser has the characteristics of different coefficient of friction and inertia, then according to different specifications of the ball to set different separation sorting parameters, The separation and sorting of casting ball and pouring riser is completed automatically by clever mechanical structure. Design production capacity of 5t/h (φ80 ball as an example), in addition to the inspection platform, all other equipment installed in the underground, set up muffler cover and dust removal equipment, reduce the labor intensity of operators, improve the working environment.

power:380KW.

Separation separation process selection flow chart:

we also provide automatic grinding ball production line, pouring machine.heat treatment equipment.hot metal transfer system. casting ball metal mold

International presence:

Zhicheng company iron mould coated sand production line has been exported to Congo, South Africa, Zimbabwe, Russia, Uzbekistan,Zambia, Vietnam, Mongolia and other countries

Certificate of honor

Invention patent: