BASIC INFO.

Product Description.

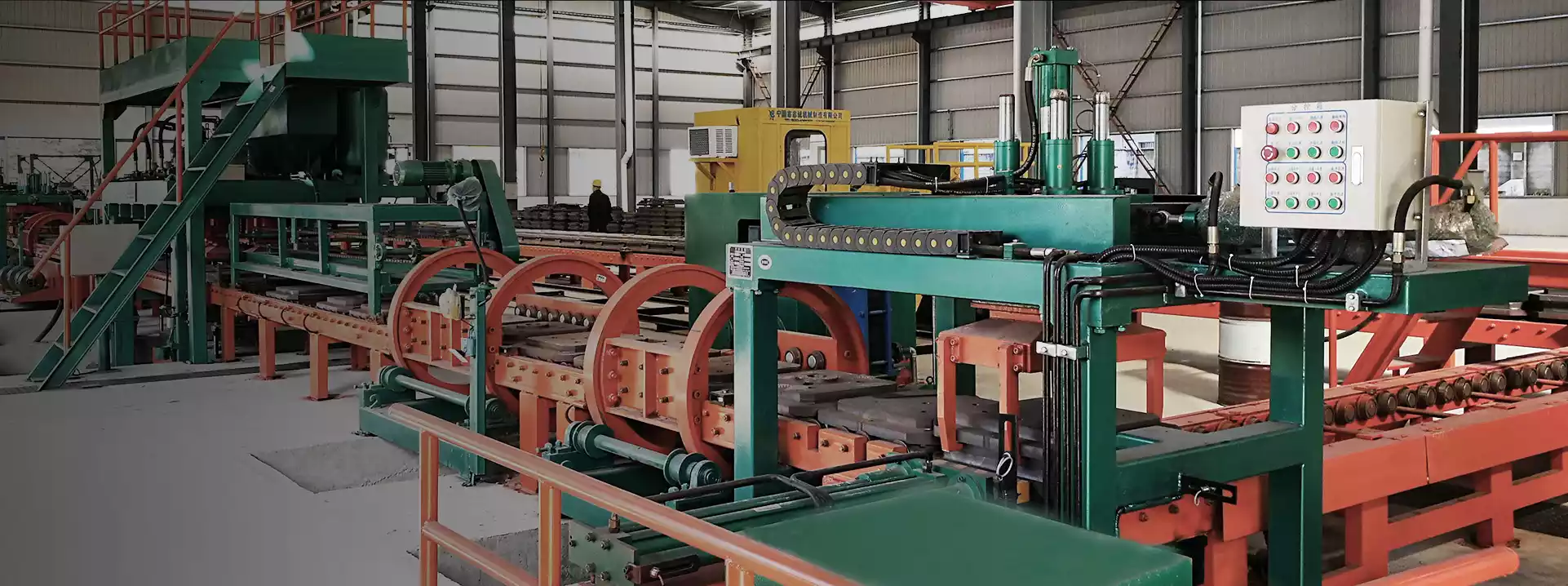

This case utilizes the performance characteristics of hydraulic and pneumatic systems, optimizes the combination, and adopts an

open+flexible conveying+multi-level supply drive method. The entire line consists of a molding line, a casting line, and two motorized roller tracks. The molding line is equipped with two stepper box feeders, which divide the molding line into three independent

operating areas: the opening area, the molding area, and the closing area. The entire line achieves non-interference in the actions of the six areas and has complementary functions. Two motorized roller tracks are used to input or output sand boxes for the molding line and the casting line, achieving the function of non-interference between the operation of the casting line and the molding line. The advantage of this operating structure is that whether the molding line or the casting line lags behind, it does not affect the operation of the other line, and the two lines have complementary functions, greatly improving the efficiency of the production line

We also provide automatic pouring machine. hot metal transfer system.heat treatment euipment.automatic separation and sort equipment.grinding ball metal mold.

Provide casting mold development for customers:

International presence:

Zhicheng company iron mould coated sand production line has been exported to Congo, South Africa, Zimbabwe, Russia, Uzbekistan,Zambia, Vietnam, Mongolia and other countries

Certificate of honor

Invention patent: