manual metal die

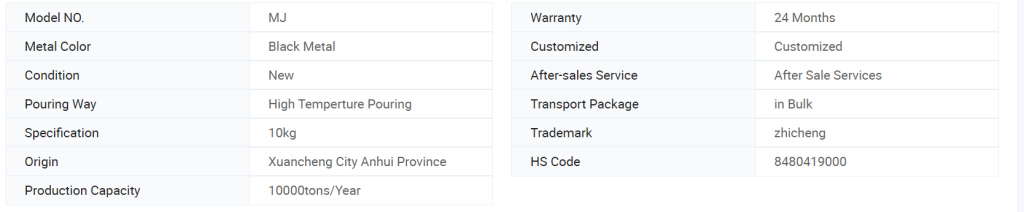

BASIC INFO.

Our company produces uniform cooling forming mold, which is a new mold improved by chilling forming mold.

advantages :

1.mold material: high silicon heat resistant cast iron. The heat transfer speed of the material is fast, not easy to deformation, the material through heat treatment after excellent mechanical properties, not easy to produce cracking phenomenon, prolong the service life. It is more than 30% longer than the service life of the same industry.

2.Hot metal in the mold is uniformly cooled into a steel ball, because the cooling speed is uniform, so the hardness of each part of the steel ball is reduced, so the steel ball is not easy to lose round, deformation, or even broken.

3.The mold can adapt to the production of high, medium and low chromium alloy casting balls, with uniform grain refinement and no casting defects.

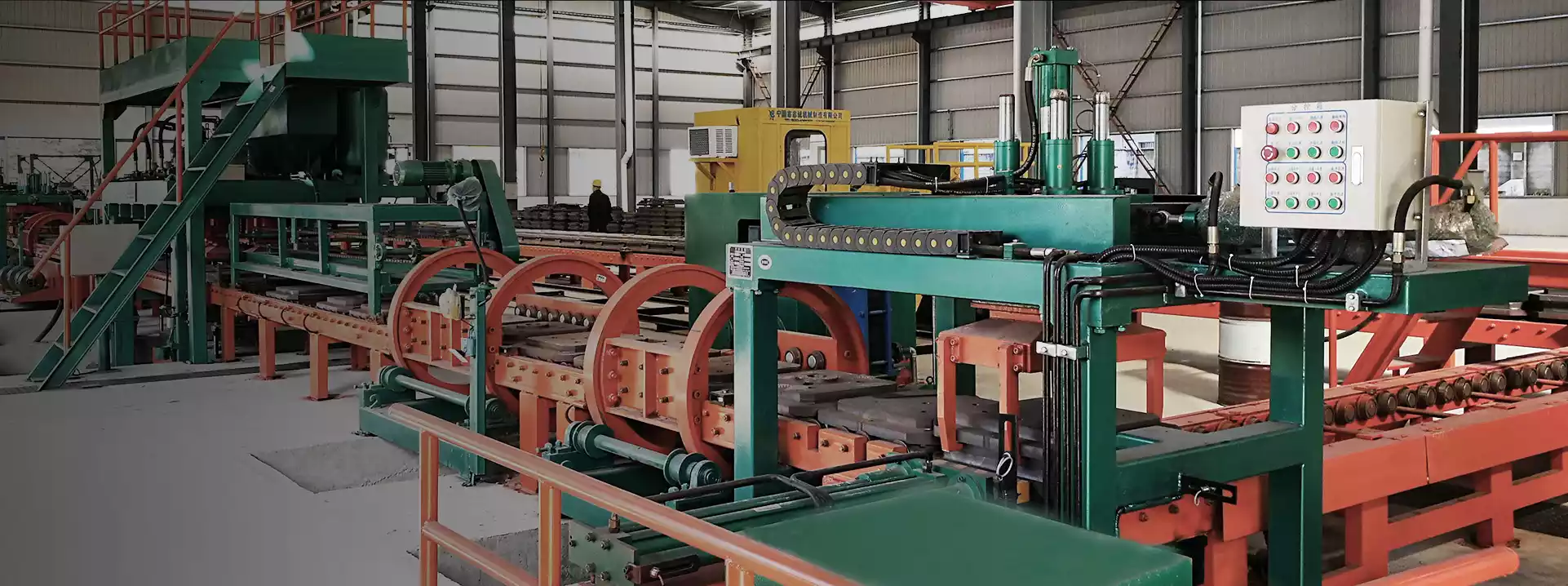

we also provide automatic grinding ball production line. automatic pouring machine. hot metal transfer equipment.heat treatment equipment(quenching+tempering).automatic separation and sort equipment. environment protection equipment and etc.

We call also provide ball mould plate.

International presence:

Zhicheng company iron mould coated sand production line has been exported to Congo, South Africa, Zimbabwe, Russia, Uzbekistan,Zambia, Vietnam, Mongolia and other countries

Certificate of honor

Invention patent: